The benefits of the COMBI-GLASS shrink hooder

The COMBI-GLASS comes with features that make it an exceptional solution:

- Superior performances: with a throughput exceeding 80 pallets/hour, the COMBI-GLASS ensures unparalleled productivity.

- Exceptional packaging quality: by eliminating wrinkles and ensuring a perfect seal on all six sides, your products are packaged with extreme care.

- Dual frame: the COMBI-GLASS combines a hooding frame and a hot air shrinking frame for optimal flexibility.

- Film compatibility: it can be used with all market-available films, including new eco-friendly films.

- Autonomy: film replacement is the simplest and quickest on the market.

- Reels management: up to 4 film reels, depending on the version.

- Thimon Human-Machine Interface: an innovative, playful, and instructive Human-Machine Interface for intuitive machine operation.

- Expandable: the COMBI-GLASS can be converted into a stretch hooder, allowing you to adapt to market needs when necessary.

The COMBI-GLASS is also available in a version with robot.

Interested in our shrink hooder?

Want to learn more about Thimon machines?

The features of the COMBI-GLASS shrink hooder

The COMBI-GLASS is equipped with advanced components to ensure high-quality packaging:

• Different dimensions available to suit your loads and environment.

• Various throughputs available to meet all your needs.

• Hot air shrinking technology: separation of the hooding and shrinking frames enables all types of packaging cycles.

• For pallets with a floor mat, heat-sealing is unmatched in the market.

• Intelligent kinematics for easy access to your pallets under the machine.

• Anticipated pallet height measurement for optimizing cycle times and consumable use.

• Reduced number of actuators for cost-effective maintenance.

• Numerous customization options are available, such as adjustment of shrinking parameters based on ambient temperature, pre-signalization of reel depletion, signaling indicators, cabinet air conditioning, different screen sizes, and many more.

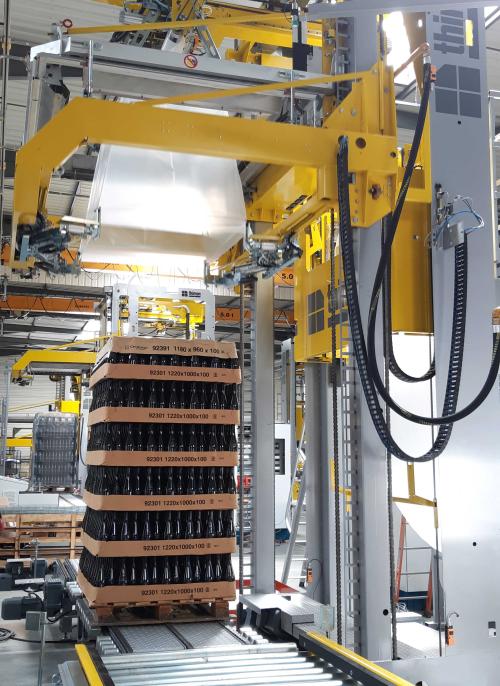

Operating principle of the COMBI-GLASS shrink hooding machine:

1. The film sleeve is unwound and cut to the appropriate length on the hood preparation module.

2. The transfer module handles, opens, and transfers the hood over the pallet being loaded.

3. The hooding frame places the hood on the load, and the shrinking frame heats it to shrink around the products.

The automation of the COMBI-GLASS includes an electrical cabinet and an independent control panel, a programmable logic controller, variable frequency drives, safety devices, and a tactile operator terminal for intuitive use.

The COMBI-GLASS is much more than a simple machine - it's a complete solution for the safe and aesthetically packaging of various products, initially designed for glass products. Its numerous advantages make the COMBI-GLASS an indispensable machine, positioning it as the benchmark for companies looking to protect their products effectively and elegantly.

Customer reviews

Our automated shrink hooding machines

COMBI-GLASS ROBOT

COMBI-GLASS ROBOT

Shrink hooder with robot

COMBI-GLASS

COMBI-GLASS

Shrink hooder for the glass market

COMBI-PAL

COMBI-PAL

Shrink hooding machine

COVER-PAL 2000

COVER-PAL 2000

Hooder

HOT-PAL